Service

Interesting facts about our production

Our heads are manufactured through flanging and dishing. In doing so, the dimensioned circular blank is machined on a dishing press several times with up to 400 tons (= flanged), till the desired radius is reached.

Our heads are manufactured through flanging and dishing. In doing so, the dimensioned circular blank is machined on a dishing press several times with up to 400 tons (= flanged), till the desired radius is reached.

Subsequently, this arched disc is given a corresponding flange on a dishing machine (= dished). In this process, the diameter of the bottom is defined to the exact millimetre.

These methods enable the production of almost every diameter between 500 mm and 4300 mm. An advantage, which a lot of our customers already plan in their products.

Grinding

Heads with a diameter of up to 4300 mm are ground in highest quality on the most modern CNC controlled grinding machines.

We grind up to a value of: Ra 0.25, suitable for subsequent electro-polishing.

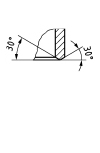

Cones

Cones with an edge length up to approx. 2000 mm are produced in a material-protective manner on a cone roller. Edge lengths up to 2500 mm are produced in best quality on our CNC sheet metal bender

Material tests

Non-destructive tests

- Visual inspections

- Dimensional tests (dimensional data sheets)

- Fluid penetration and X-ray tests

- Ultrasonic tests

- Delta ferrite measurements

- Documentation of roughness values

Destructive tests

- Tensile, bending and notch impact tests

- PMI

- Macro and micro tests

- Material tests

The tests done as well as materials used are documented.

Because JÜNGER focusses on quality