Production

Interesting facts about our production

Our heads are manufactured through flanging and dishing. In doing so, the dimensioned circular blank is machined on a dishing press several times with up to 400 tons (= flanged), till the desired radius is reached.

Our heads are manufactured through flanging and dishing. In doing so, the dimensioned circular blank is machined on a dishing press several times with up to 400 tons (= flanged), till the desired radius is reached.

Subsequently, this arched disc is given a corresponding flange on a dishing machine (= dished). In this process, the diameter of the bottom is defined to the exact millimetre.

These methods enable the production of almost every diameter between 500 mm and 4300 mm. An advantage, which a lot of our customers already plan in their products.

We deliver precise heads manufactured with lowest tolerances for each requirement in different diameters and shapes!

For this reason, our heads can be used without any problem also in automatic production lines.

We would also be happy to advise you personally and reply to all your queries. Or else you can use our HOTLINE!

Materials:

- Stainless steel

- Hasteloy™

- Aluminium

- Special steels

- Copper

Please ask for the materials and heads in special shapes not mentioned in our delivery programme. We will endeavour to find a solution.

We manufacture according to:

- AD2000 Handout HP0

- AD2000 Handout W0 / TRD100

- PED 2014/68/EU

- DIN EN 13445

- DIN EN 3834-3

Test certificates according to EN 10204

- Company certificate 2.2

- Acceptance test certificate 3.1

- Acceptance test certificate 3.2 (TÜV)

Parts without production and testing requirements:

- Certificate of compliance

Additional work:

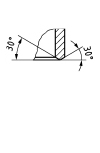

- Beveling und tapering up to Da = 2750 mm on lathe machine

- Beveling and tapering up to Da = 4300 mm on edge grinding machine

- Plasma, UP or WIG welding

- Plasma cutting of centre holes and sections also according to DXF templates

- Necked-in openings and extrusions up to D = 850 mm clear diameter

- Annealing up to 1150°C as per AD 2000 – HP 7

- Pickling, blasting, glass bead blasting

- Grinding up to Ra = 0.25. Ground structure suitable for later electro-polishing

- Sanding of the welded seams

- Production of heads / cones with thermal plate or pillow plate

Well trained and committed employees

are responsible for our quality

Because JÜNGER focusses on quality